A workshop may be a room or building which provides both the area and tools (or machinery) that may be required for the manufacture or repair of manufactured goods.

In our repair shop, repair operations take place as desired by the customers. Our research and development implement some of their innovative ideas in this small area only. If any technician or mechanic wants to practice some automotive experiments and gain knowledge, we give ample time, space and required tools for this purpose. This helps our garage to get experienced servicemen and technicians.

From an owner's or manager's perspective, auto workshop safety begins with a proactive approach focused on following basic safety practices. Prominently posted signs and written policies remind employees against taking shortcuts that result in job-related injuries. Protective clothing is also essential to avoid exposure to paint additives or solvents that can cause work-related asthma. To ensure broad acceptance and compliance, management should enlist workers, whenever possible, to help draft and review safety policies.

WORKSHOP

Learning that we give to our technicians:

Clear Work Areas

Keeping work areas free of clutter is an important, step in running a safe and productiveworkshop. Slip and fall injuries are more likely to happen when technicians must constantly walk through piles of discarded parts and other body shop debris. Shops should create formal emergency response plans, so that employees know to react and stay safe.

Hazardous Materials Awareness

Auto repair technicians are exposed to many harmful chemicals. To avoid this, steps can be taken by posting Materials Safety Data Sheets that outline a product's potential health hazards, and institute any protective measures that the manufacturer or supplier recommends.

Injury Prevention

Back injuries are the costliest illnesses, because of the length of time lost. We can protect them by having workers follow common sense measures, such as using jacks and lifting aids while they're handling heavy parts during the installation process, for example.

Protective Equipment

Requiring appropriate protective gear minimizes eye and finger lacerations, which are common auto body shop injuries. Technicians should use appropriate eyewear, and protective gloves available to prevent cuts from glass, sheet metal or other jagged objects. To minimize the risk of work-related asthma, servicemen should use chemical-resistant protective suits, head socks, particle masks, and other coverings.For best results, we revive safety policies with technicians, and continually review them during monthly shop safety meetings.

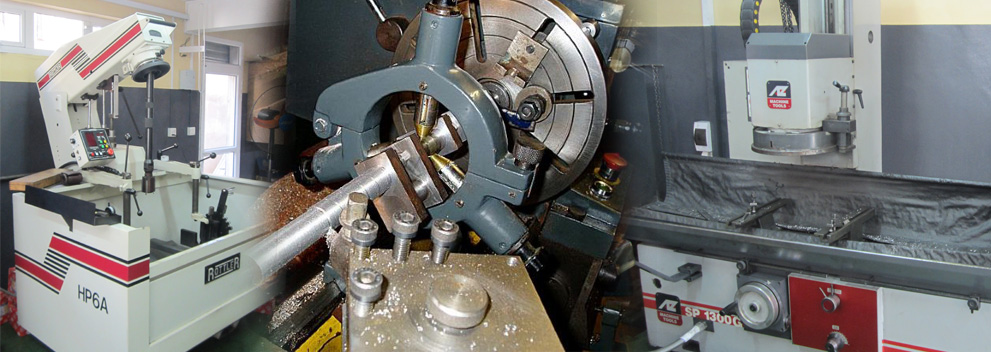

Our workshops contain a wide range of automotive spare parts of different brands, from Izumi to Aisin to Exedy. We also keep a huge stock of all desired spare parts. Machineries include Rottler F54A boring machine, AZ spa surfacing machine, Brake Lathe of Hunter brand and Rottler HP6A Honing machine.

Our main motive to have workshops is to allowing everyone some personal attention and the chance to be heard about our business and its future. They're conducted by experienced team members for new technicians giving them learning and practical experience knowledge. This helps to learn new technicians about all brands spare parts so that they will not make any mistake while attending to any customers. It's a great way to teach hands-on skills because it offers servicemen a chance to try out new methods and fail in a safe situation. Failure is often the best teacher, and failure in this instance doesn't carry a cost.

At the same time, feedback, from bo

th the presenter and peers in the group, helps a participant understand what he can do to avoid failure in a real situation. A workshop provides a way to create an intensive practical experience in a short amount of time, when the time for a more comprehensive effort may not be available. Technicians may be working or may simply be unwilling to commit large amounts of time. A workshop can introduce a new concept, spurring participants to investigate it further on their own, or can demonstrate and encourage the practice of actual methods.

All rights reserved by Roshan Autoparts

Designed and Developed by Mirackle Solutions