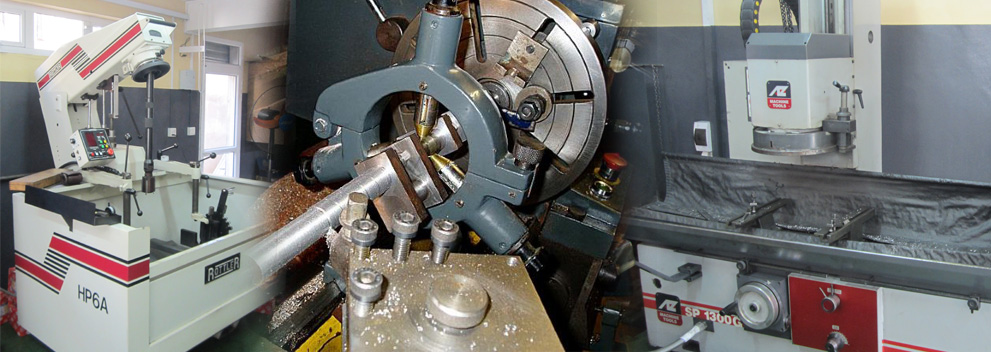

We use AZ spa surfacing machine of model SP 1300G for this particular service.

Specifications include:

» |

Max. grinding width: 350 mm |

» |

Length: 1000 mm G |

» |

Grinding Power : 6 kW |

» |

Stroke: 1100 mm |

Cylinder head surfacing is an important part of any automobile repair shop and the ability to surface head quickly is the key of success.

Our surface models offer all of the versatility with none of the hassle. It will ensure that the gasket is seated correctly and compressed evenly. An even compression on the seal will help assure that it won't leak. Another factor to take into consideration is that it might be a rough patch in the cylinder head surface that is causing the leak. In that case, you would have to have it resurfaced, or else it will never seal.

We provide cylinder heads and blocks that are needed to resurface or to restore flatness or to improve the surface finish, or milled to change the deck height for a variety of reasons. We resurface the head after welds or other repairs that have been made, or milled to increase the compression ratio. We give additional service by cleaning the manifold surfaces of the head due to corrosion or erosion, or the angle changed slightly to better align with an aftermarket intake manifold. The deck surface on the block may need to be resurfaced. Whatever the reason is for resurfacing these parts, we do it quickly, efficiently and correctly. Mistakes here can be very expensive, because once metal has been removed there is no putting it back.

Some of the mistakes that we try to avoid while surfacing any vehicle are:

» |

Misalignment |

» |

Wrong Feed Rate/Speed |

» |

Not Checking Flatness |

» |

Avoid using Outdated Equipment |

» |

Resurfacing Diesel Heads with precombustion Chamber Cups |

» |

Lack of Maintenance |

» |

Wrong Surface Finish |

» |

Removing Gaskets The Wrong Way |

» |

Taking Too Much Metal |

» |

Using the Wrong Tools |

» |

Trying To Resurface Rusty Heads |

» |

Not Wearing Eye Protection |