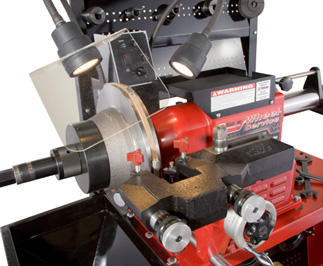

Rottler F54A boring machine

We have Rottler F54A boring machine which is a heavy duty machine, designed for large capacity machine work in repair shops. By the help of this machine, large sleeve cuts can be taken at high spindle RPMs and in many blocks, one pass sleeve cuts are possible to increase productivity. Programmable counter boring operations with this model eliminates guess work and provides added timesaving. This massive one piece stress relieved, precision machine base casting allows the fixturing of large diesel engine blocks. The F54A machines can also handle small jobs with optional cutter heads. The A models store programs in their memory for future use. It does everything except the machine doesn’t move from hole to hole. The A model will bore to the exact programmed depth centrally and move tool away from the cylinder wall and rapid to the upper start position, ready for the next operation. The F54A machines can also handle small jobs with optional cutter heads. The A models store programs in their memory for future use.